2023 // 2024

OD61 in “HAL 16”

Hal 16

Hal 16, located in Helsingoer (northern Sealand), is a community for people with wooden boats, who needs to do work on their own wooden boat. DIVA arrived in Hal 16 in November and she was back in the water, end of march 2024.

In the summer, Diva was driven on a trailer to Stockholm, and got herself a new cockpit sole, which was made by the highly skilled people at Stockholms Båtsnickeri.

Cracks repaired, below and above waterline

-

It is quite nerve wracking to cut into this delicate spot on the boat, but there is no way around it.

-

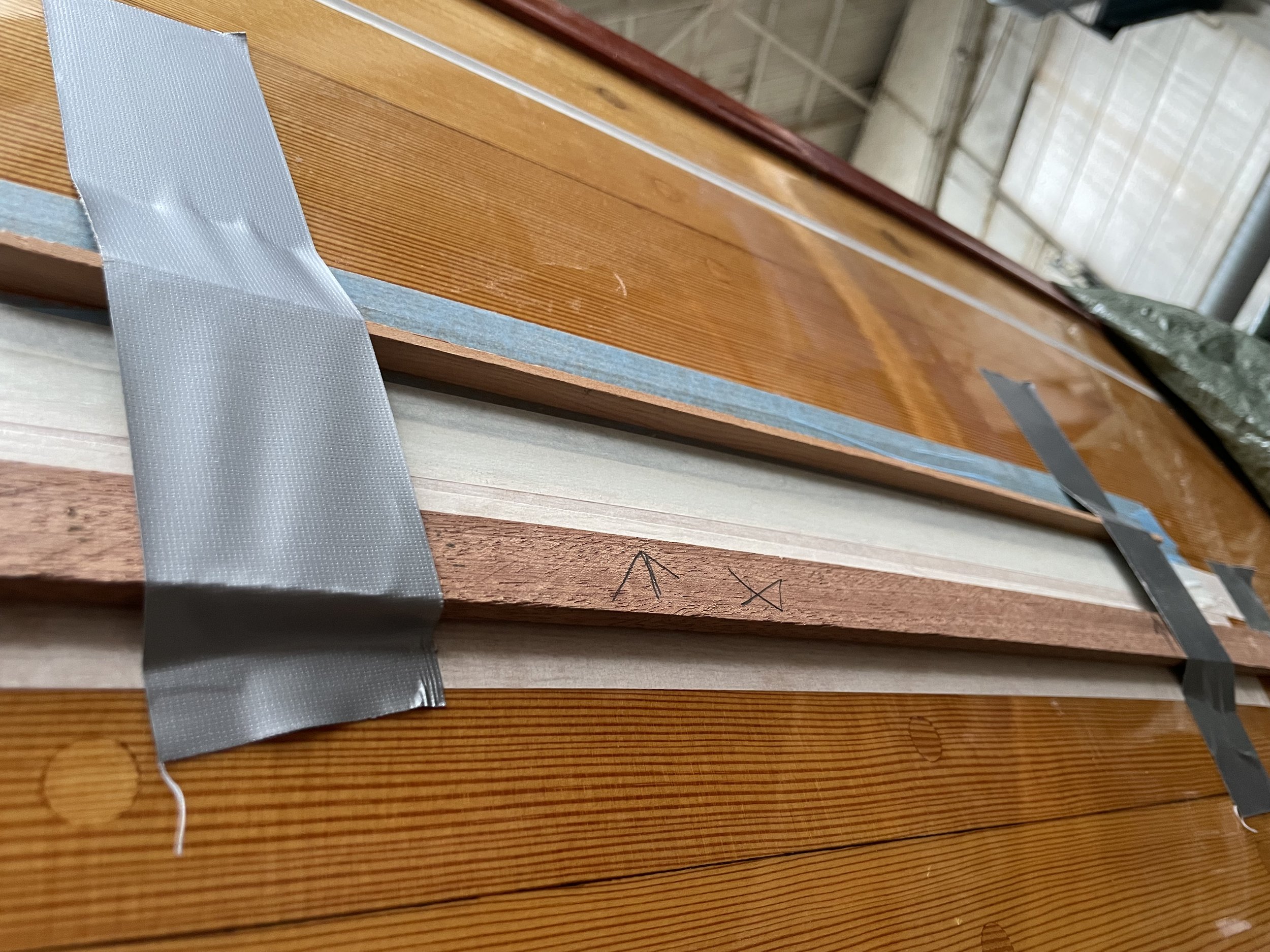

Gluing in a piece of oregon pine.

-

Now the repair will allways be part of Diva's history. I might redo this repair next winter, as I am not entirely happy with the result.

-

Milling the crack, to make room for a piece to be glued in. The Mahogany piece below the milled line is the lead for the millingmachine.

-

New piece of oregon pine has been glued in and leveled out.

-

Several small cracks needed repair to prevent water ingress.

New floor timber, and last, new keelbolt

-

Templating for new floor timber.

-

Transferring the pattern to the wonderful, aged and dried oak.

-

Milling out the pocket to access the keel bolt end.

-

Keel bolt is out. Bent, and in some places a bit thinner. Still strong, but in need of replacement.

-

Taking out the screws that go through the planking and into the floor timbers. Not easy to get out.

-

Old floor timber is out. It had a few bad spots, but nothing serious. No issues under the floor timber.

-

Milling the new floor timber.

-

Adjusting, to get a perfect fit.

-

Transferring the placement of the hole, using plexiglas.

-

New, stainless steel bolt is in and fits perfectly.

-

Pocket hole is filled and glased over. Still needs fairing, primer and bottom paint.

-

Job done. The beefy fitting is one of two center lift fittings. Machined by Walsteds.

Speech, for a small croud

Replacing the mainsheet travellar post

-

The old post was a little bit crusty. We took the opportunity to lengthen the new post.

-

Working on the new post.

-

Rounding over the edges.

-

Cutting a groove for the travellar.

-

Seems to be a perfect fit.

-

Dryfitting the new post.

-

The old, iron fitting for the mainsheet travellar post needs to be replaced.

-

Stage 2 template for a new mainsheet travellar post fitting.

-

The new, beefy fitting was machined by Walsteds. It is seated and fastened through the floor timbers, rather than bolted through the keel timber. We can still bolt it through the keel timber.

-

Fitting the new and varnished post.

-

Strong, slightly higher post and with shiny, re-chromed, original travellar.

-

Job done, allmost. Still needs plugs.

Stay or go?

-

Should the old teak cockpit sole stay or go? A closer look reveals a thinned sole, with lots of repairs, but could still be used. We have been looking for approx. 2 years for quarter sawn teak to replace this sole.

-

We went to Stockholm and found Stockholms Båtsnickeri with very skilled people, who found us the perfect, quarter sawn teak plank for our new sole.

-

Couldn't be more happy with the result. A huge shout out to owner of Stockholms Båtsnickeri, Andreas and his highly skilled employees. Thanks to Alex for finding the teak plank and thanks to Niklas and Andreas for the fantastic job and efforts to make this happen.

Moments