Home

2020 // 2021

We spent 5 days sailing to Walsted’s on Thurø (Island of Funen).

Why go through all the trouble? If I had the option to trailer the boat, I probably would. However, an incredible weather window opened, and my wife and I had the opportunity to take advantage of it. Off we went, and it turned out to be the best week on the water of the season. Five wonderful, wonderful days with perfect sailing conditions. What a gift and even so late in the season!

I met Henning Bøgh from Walsted’s at a boat show in Ishøj (island of Zealand) and had a great conversation with Henning about, among other things, my Knarr, which led us to Walsted’s to primarily have the keel bolts inspected. Now, I can finally put my worries about the keel bolts to rest. But there were more than just the keel bolts that needed attention.

I had a feeling that OD 61 had come home. Thanks to the whole yard, and especially Henning Bøgh, for the way we were treated, making us feel at home.

-

Rot Under the Mast Track

A single bad keel bolt had resulted in some rot in the keel. Several other keel bolts that were inspected were in good condition but was also replaced with new stainless steel bolts. A relatively large part of the upper layer of the keel was replaced. The rusty mast track was replaced with a stainless steel one.

-

5 New Floors

As always, the season's projects turned out to be more extensive than initially anticipated, but you have to do what's necessary when you're at it. 5 new floors, 7 new stainless steel keel bolts, and as seen in the picture, the little bit of rot that extended a long way along the keel was removed and repaired with a new piece.

Amazing work carried out by Walsted’s.

And next year, we'll replace an additional 2 floors and 3 keel bolts.

-

Nothing Is Easy

The floors are screwed in from the outside, and the ends of the keel bolts need to be located in pockets in the keel. Here, you can see the mounting holes on three of the five replaced floors and two open pockets for the keel bolt nuts at the keel end.

-

Dry Oak

Dry oak is required to make the new floors. It's not easy to find dry wood in the required dimensions, even for a Knarr-sized boat. The wood needs to be processed, planed, cut, and fitted. Holes need to be drilled for the keel bolts, and then it needs to be adjusted once again when it's installed in the boat.

Not for Appearances

It looks beautiful. But it's the structure of the boat, and it needs to be solidly made. The craftsmanship of the Walsteds boat builders is simply outstanding. There are a couple of floor timbers that are varnished so the beautiful wood can be seen, even though it's only visible when the cabin sole is lifted up.

The new stainless steel mast track has a new contact surface.

-

Rest in Peace

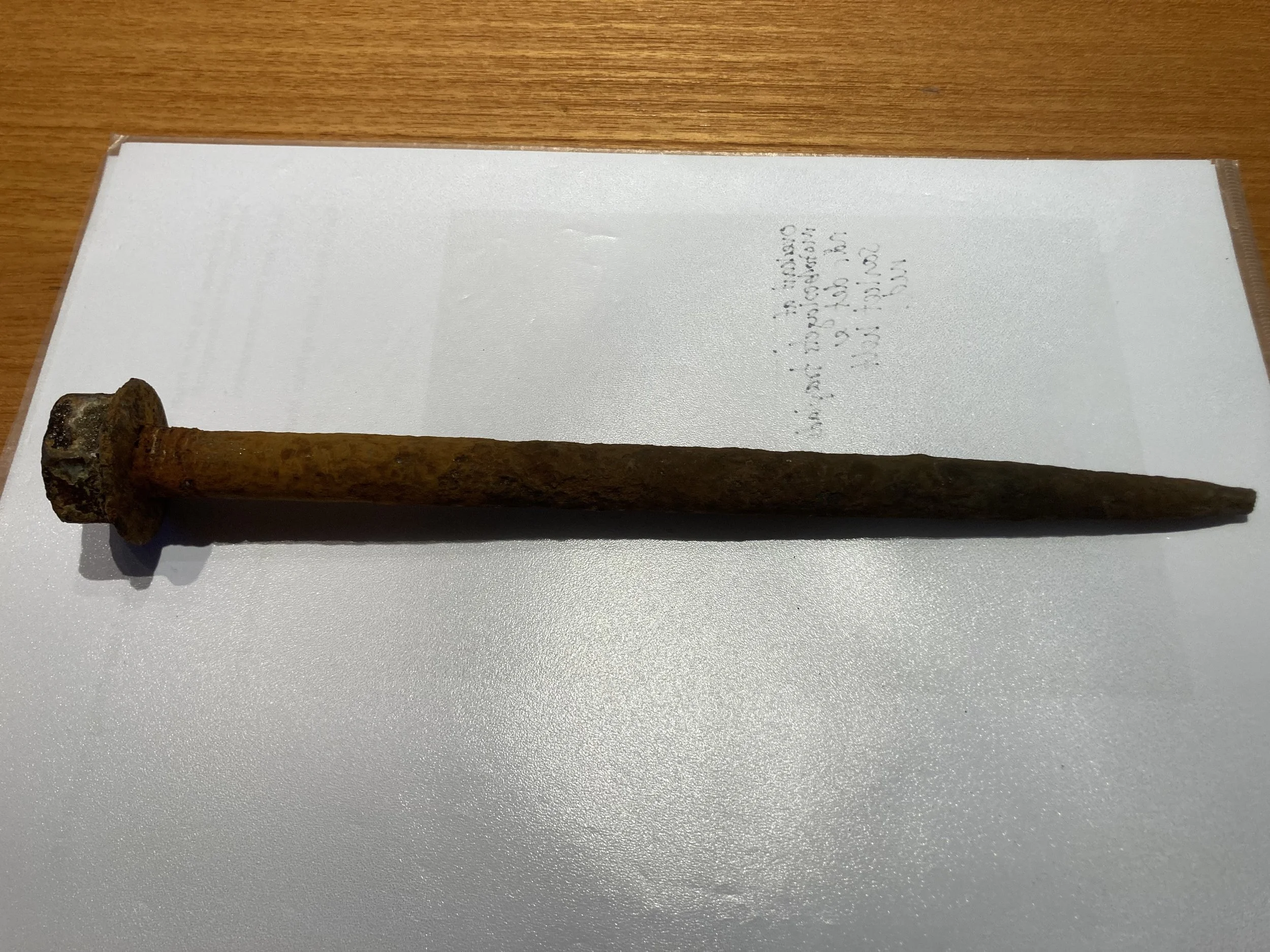

It was high time to get this keel bolt replaced.

The other keel bolts, that were checked, were in much better condition but were still replaced with new stainless steel bolts.Now we can sleep soundly on the boat.

-

Inspection of Previous Repair

Fortunately, we found no issues with the previous repair.

A new plate of high-quality marine plywood was installed.

Freeboard Lacquering

The annual lacquering of the hull sides turned out really well.

We painted the hull sides ourselves and chose to do it in the fall when the temperature were still good. Springtime can be a problem with temperatures being too cold. We drove to Thurø, did all the preparations, stayed overnight, and painted the next day. A really pleasant working trip. Luckily, Denmark is not that big.

From our trip back and forth to Walsteds